Our Products

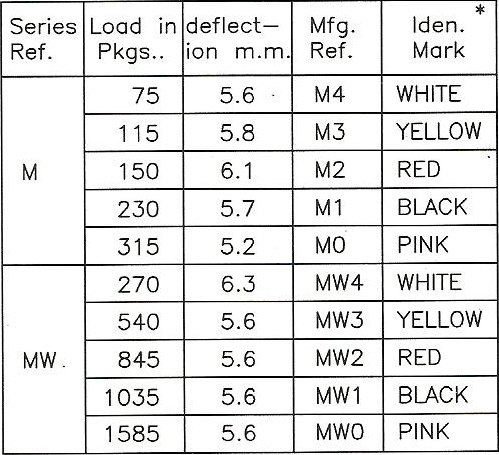

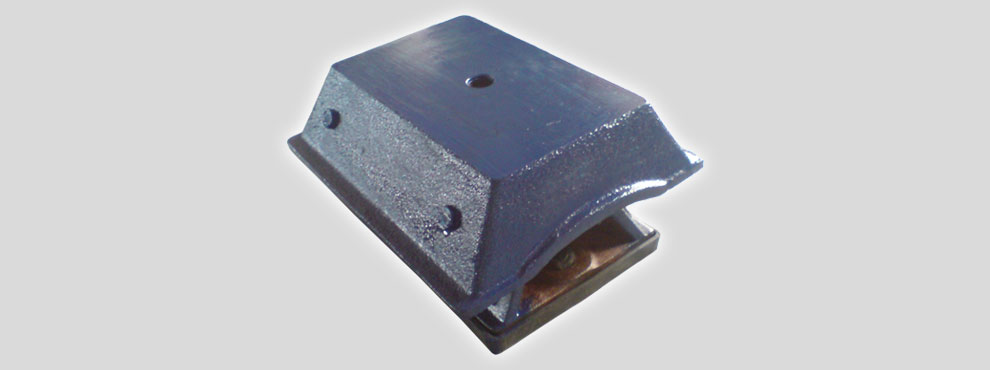

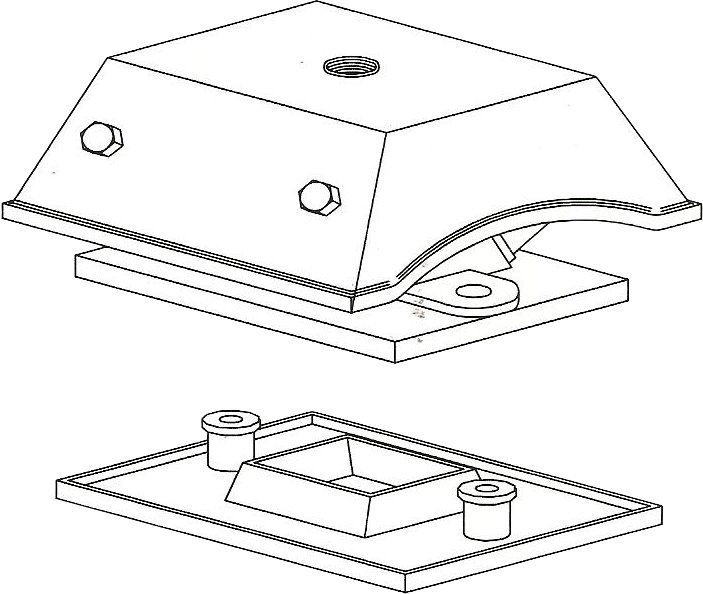

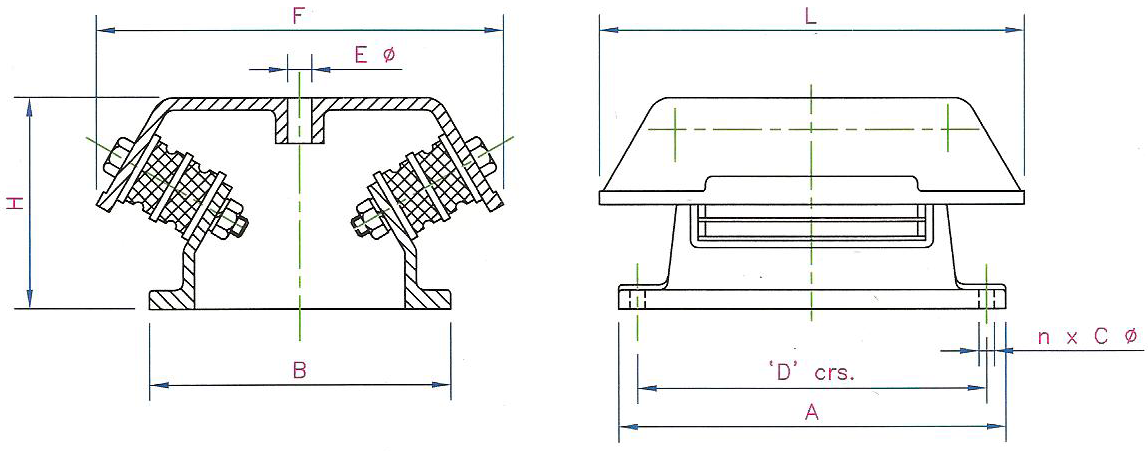

Anti Vibration Mountings (Type - M & MW)

Salient Features

No grouting/Anchor Bolts

Applications

Diesel Engines

Generator Sets

Fans

Compressors

Punps

Power Press

Printing & Textile m/cs

Material Handling Equipments

The sandwich design mountings fixed in angular position loaded in shear and compression, the rubber used to the best advantage to provide having multi directional stiffness results into 70% insulation which is adequate for most of the applications for isolation of vibrations.

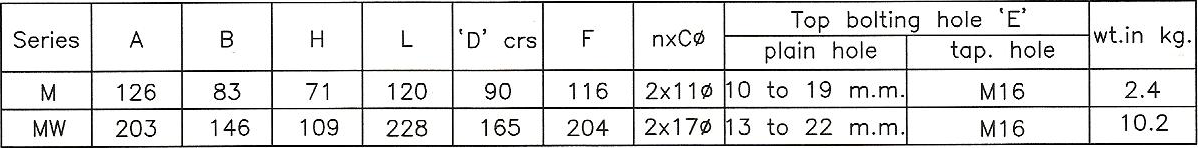

Vibration Transmission / Disturbing Frequency Chart

| Disturbing Frequency | Deflection | |

| c.p.m. | Hz | m.m. |

| 500 | 8.33 | 15 |

| 600 | 10.00 | 11.0 |

| 700 | 11.60 | 9.0 |

| 800 | 13.40 | 6.3 |

| 900 | 15.00 | 5.0 |

| 1000 | 16.75 | 3.7 |

| 1250 | 20.80 | 2.6 |

| 1400 | 23.33 | 2.2 |

| 1450 | 24.10 | 2.0 |

| 1500 | 25.00 | 1.9 |

| 1750 | 29.16 | 1.4 |

| 2000 | 33.33 | 1.0 |

Data Rqquired for the section of A.V.M.s

- Total wt. of equipment

- Dimensional data with C.G. of foundation frame.

- Wt. distribution over mounting points.

- Frequency of the offending vibration i.e. disturbing frequency.

- Environmental conditions ie. presence of heat & corrosive & oil mist etc.

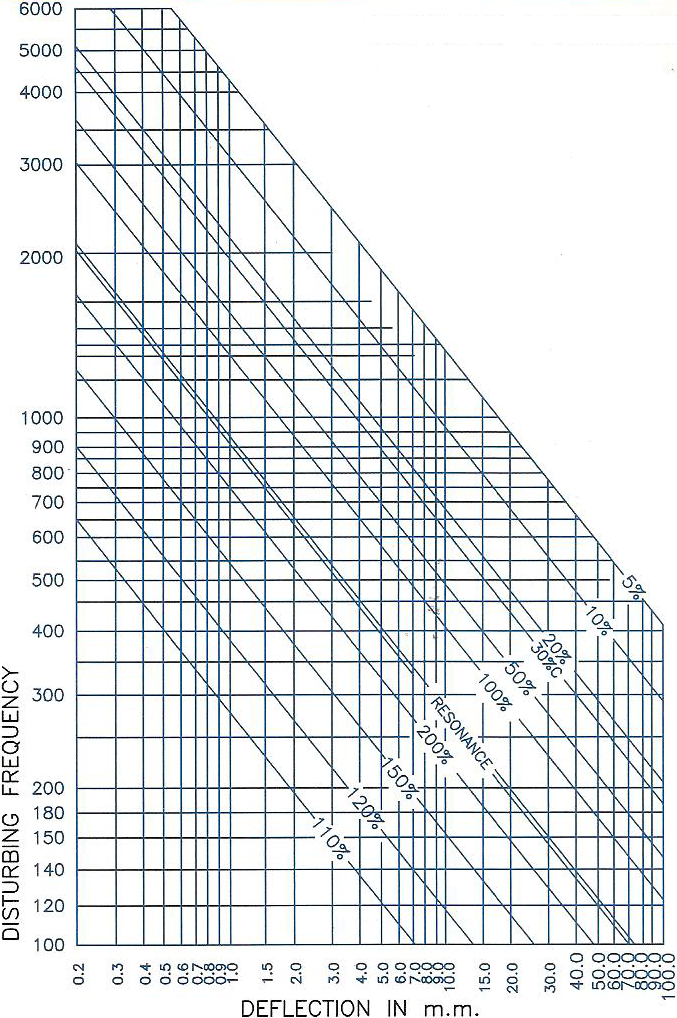

How to select the Cushfoot Mounting

- Consider each mounting point separately.

- Draw a vertical line upwards from the minimum deflection needed to give adequate insulation, until it meets the nearest suitable mounting line.

- This will give the required mounting and actual deflection is given by a vertical line downwards from this point to the deflection scale.

- Repeat this proedure for uneven distributed load point mountings.

- For selection of mountings for critical applications kindly contact Machweld.